Powder Coating

How is Powder Coating Done?

Powder coating is a type of dry coating, which is applied as a free-flowing, dry powder. The main difference between a conventional liquid paint and a powder coating is that, the powder coating does not require a solvent to keep the binder and filler parts in a liquid suspension form. The coating is typically applied electrostatically and is then cured under heat to allow it to flow and form a “skin.”

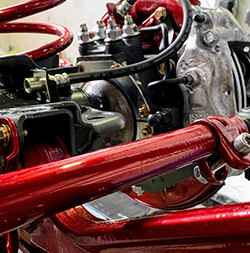

The powder may be a thermoplastic or a thermoset polymer. It is usually used to create a hard finish that is tougher than conventional paint. Powder coating is mainly used for coating of metals, such as “white goods”, aluminium extrusions, and automobile and motorcycle parts.

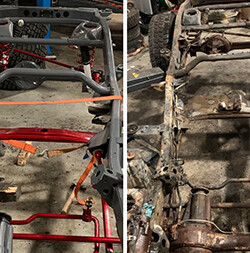

Preparation is key for powder coating, we dip most of parts and then blast on all our non ferious parts we vapour blast to assure the best finish to the product.

To Powder Coat or not Powder Coat?

Almost any metal part that can be painted, can be powder coated, with a few caveats. In order to use powder, parts must be able to withstand the curing temperatures of powder. This usually means 180°-200°C for 15-30 minutes. Parts must also be able to withstand the additional coating thickness of powder. Powder does go on heavier than typical paint.

For further advice or any questions, you may have about powder coating your particular project, we hold a range of standard colours in stock and we are happy to produce custom colours to order.

Samples and prototypes can also be produced at cost.

Please feel free to discuss with us any specific requirements you may have.